Flight Computer Alpha (ESP8266 based Model Rocket Flight Computer)

System Modules

Flight Computer Alpha: First Steps into Professional PCB Design

Project Overview

Flight Computer Alpha represents a pivotal transition point in my engineering development—my first venture into surface-mount component assembly and custom PCB fabrication. Born from the experience of flying Finnley, a medium-power rocket with an actively stabilized canard control system, this flight computer was designed to address the significant size and reliability limitations of hand-soldered perfboard construction while serving as a learning platform for professional manufacturing techniques.

The Finnley project had demonstrated the viability of scratch-built flight control systems, successfully implementing PID-based active stabilization using a custom hand-soldered flight computer (FC2) built on perfboard. However, FC2's approximately 2.5" × 5" form factor represented both a weight penalty and packaging challenge for future rocket designs. More critically, the hand-soldered construction introduced reliability concerns and made reproducibility essentially impossible. Flight Computer Alpha was conceived to overcome these limitations while teaching me the skills necessary for modern electronics design.

Technical Architecture and Design Decisions

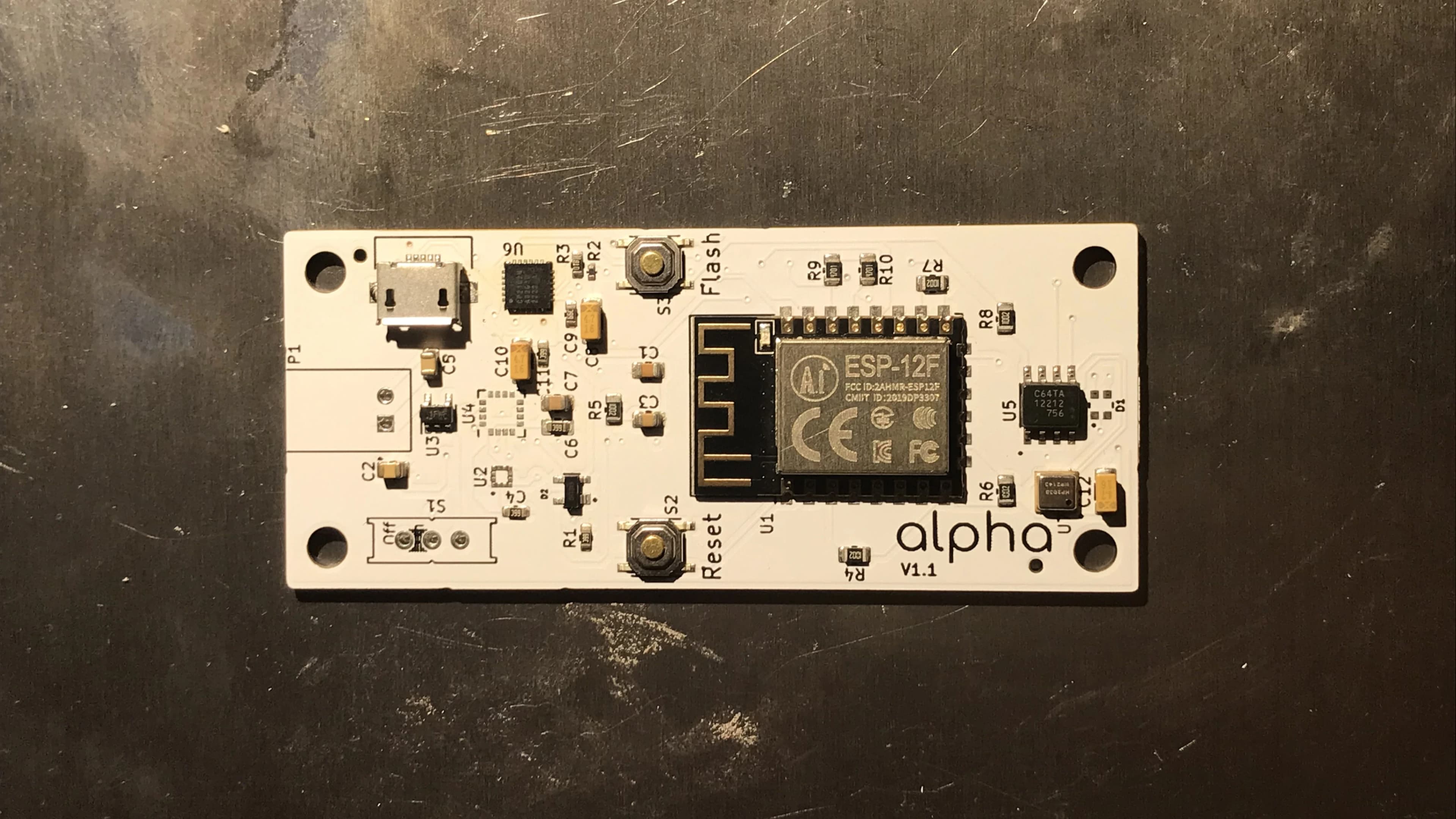

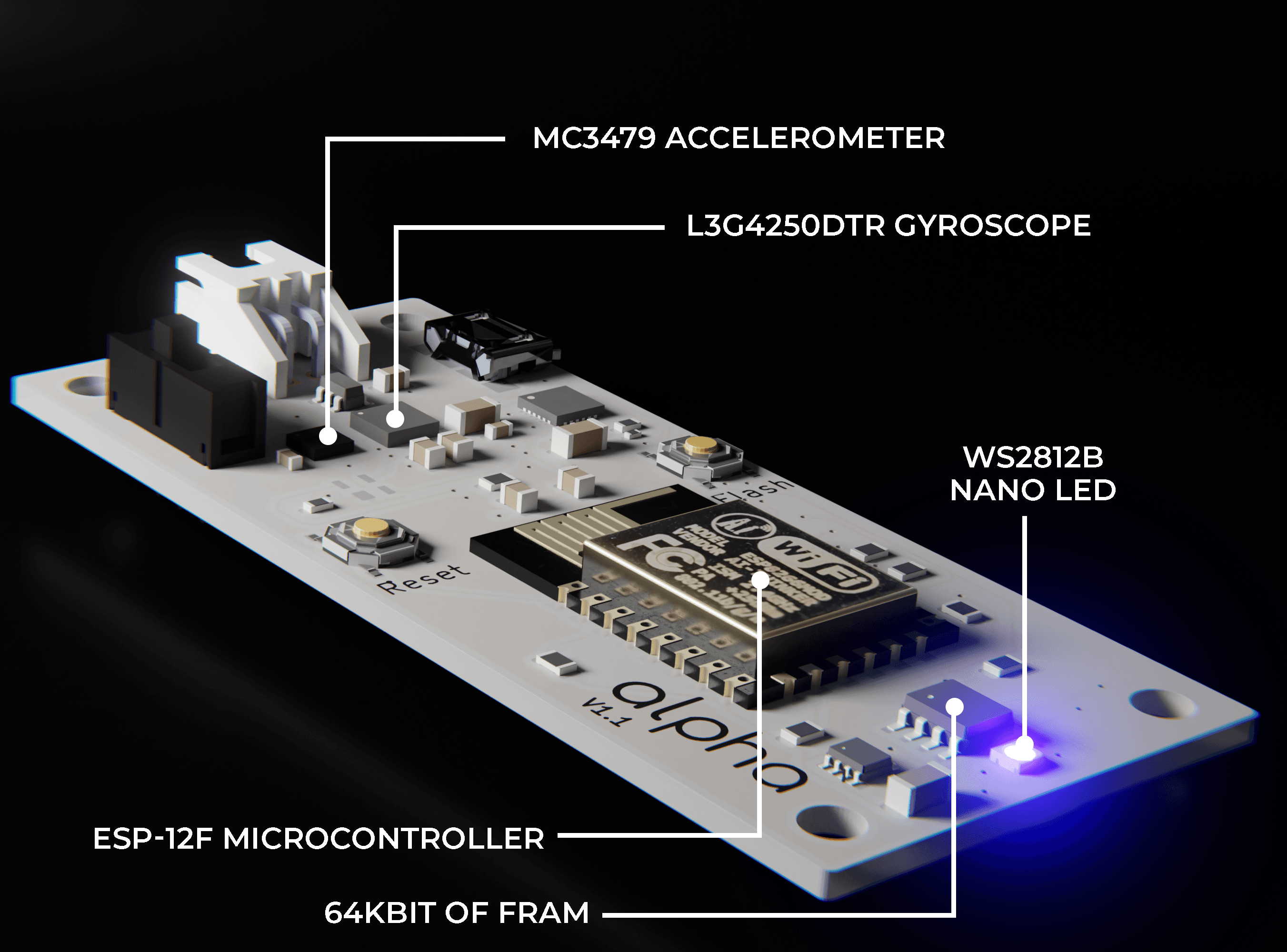

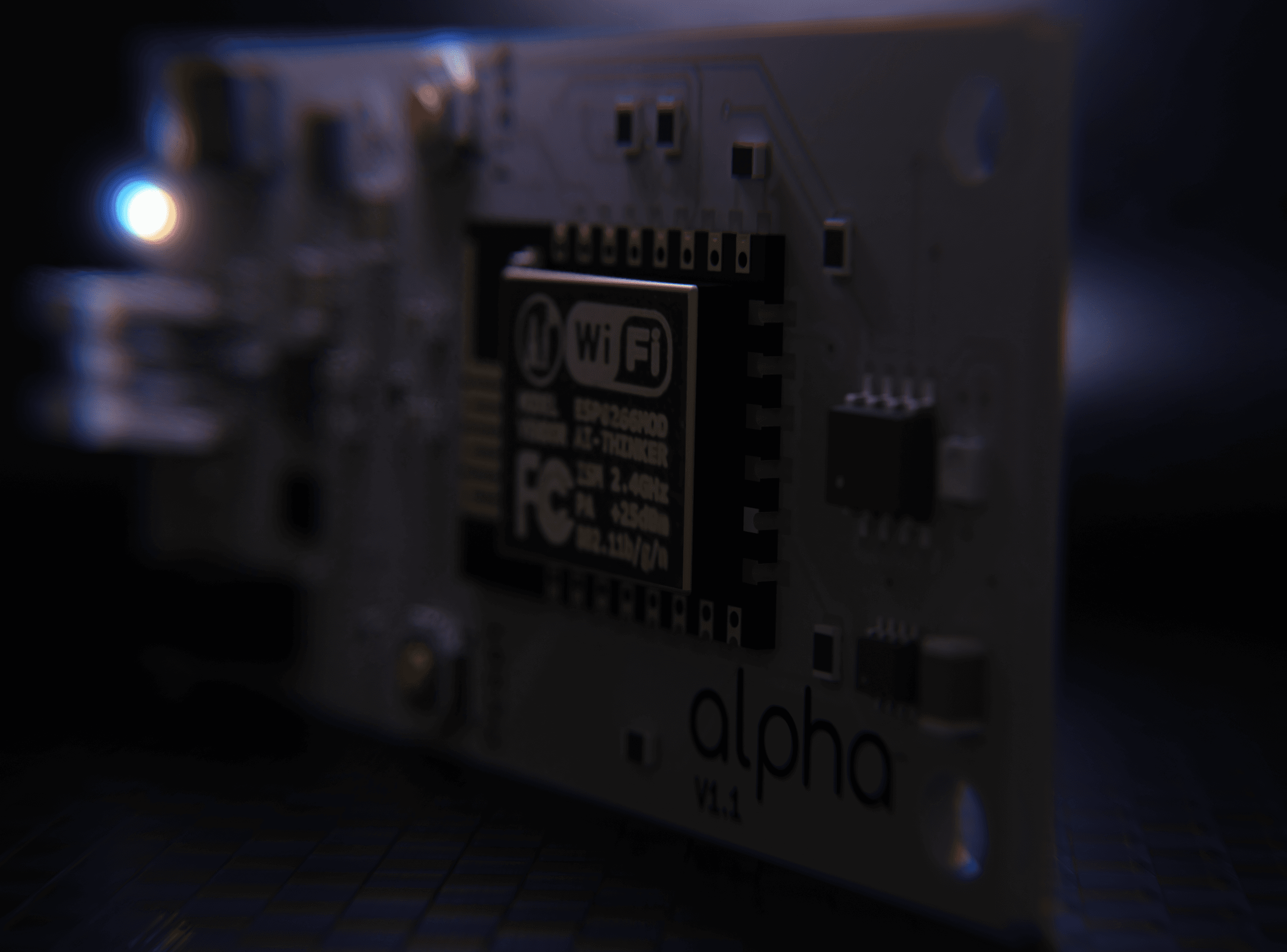

The board centers around an ESP12F microcontroller module, a significant departure from FC2's Adafruit Feather M0. The ESP12F brought integrated WiFi capabilities to the table—though this feature wasn't critical for the immediate application, it represented forward-thinking design that would prove valuable in later projects. More importantly, the module's compact surface-mount form factor forced me to engage with SMD assembly techniques from the outset.

I retained the proven sensor suite from Finnley: a 3-axis accelerometer, gyroscope, and barometric pressure sensor. These components had demonstrated their effectiveness during Finnley's wind tunnel validation and flight test, providing the real-time state estimation necessary for flight data logging and potential control applications. By keeping the sensor architecture consistent, I could focus my learning energy on the manufacturing and assembly aspects rather than re-validating an entirely new sensing approach.

One of the most significant improvements over FC2 was the integration of onboard flash storage and a USB interface for data retrieval. Finnley's flight had suffered from telemetry data loss when the SD card failed to record properly, leaving only partial radio telemetry for post-flight analysis. The USB interface represented a dramatic usability improvement—instead of relying on LoRa wireless communication or dealing with SD card compatibility issues, flight logs could be downloaded directly via a simple USB connection. This seemingly small detail would prove crucial in later projects where reliable data retrieval was safety-critical.

Manufacturing and Miniaturization Achievement

The physical transformation from FC2 to Flight Computer Alpha was dramatic. Where FC2 occupied roughly 12.5 square inches of perfboard, Flight Computer Alpha compressed similar functionality into a form factor comparable to an Arduino Nano—approximately 1-2 square inches. This represented an 85-90% reduction in board area, achieved through the transition to surface-mount components and professional PCB layout.

I fabricated the boards through JLCPCB, my first experience with professional PCB manufacturing services. The process of preparing Gerber files, selecting board specifications, and managing the manufacturing workflow was entirely new territory. Receiving those first professionally manufactured boards—with crisp silkscreen, precise pad spacing, and uniform solder mask—was a revelatory moment that highlighted just how far removed hand-soldered perfboard was from modern electronics production standards.

The surface-mount assembly process itself presented a steep learning curve. Without the through-hole component leads I'd relied on for FC2, every component required precise placement and careful soldering technique. I developed proficiency with solder paste application, learned to manage thermal mass differences between small passives and larger ICs, and gained appreciation for the unforgiving nature of SMD rework.

Project Outcome and Legacy

Flight Computer Alpha never flew in a rocket. As the project progressed, my interests evolved, and I found myself applying the knowledge gained from this design to a higher-stakes application: an open-source skydiving altimeter. The altimeter project demanded everything I'd learned from Flight Computer Alpha—professional PCB fabrication, SMD assembly, USB data interfaces, and onboard flash storage—but in a life-safety context where reliability was non-negotiable.

In retrospect, this trajectory makes Flight Computer Alpha's contribution clear: it served as a crucial bridge project that allowed me to develop professional electronics skills in a lower-stakes environment before applying them to safety-critical equipment. The rocketry application provided sufficient motivation to push through the learning curve of SMD work and PCB design, while the consequences of early mistakes remained limited to failed boards rather than failed safety equipment.

The technical decisions made during Flight Computer Alpha's design proved remarkably prescient. The ESP12F's integrated WiFi, though unused in this project, would become relevant in future designs. The USB interface pattern became standard in my subsequent work. The flash storage architecture was refined and strengthened for the skydiving altimeter. Even the compact form factor—initially pursued to reduce rocket payload weight—translated directly to the wearability requirements of a skydiver-worn device.

Reflection

Flight Computer Alpha exemplifies the value of intermediate projects in technical skill development. While it never achieved its nominal goal of flying in a rocket, it accomplished something more valuable: it transformed my capabilities as an electronics designer. The project proved that sophisticated, miniaturized electronics were within reach of individual makers willing to engage with modern manufacturing processes. It validated that the jump from hobbyist hand-soldering to professional PCB design, while significant, was achievable through focused effort on a well-scoped project.

Most importantly, Flight Computer Alpha established a foundation of manufacturing competence and design confidence that enabled more ambitious projects. Without this stepping stone, the skydiving altimeter project—with its demands for reliability, miniaturization, and robust data handling—would have represented too large a leap from FC2's hand-soldered perfboard construction.